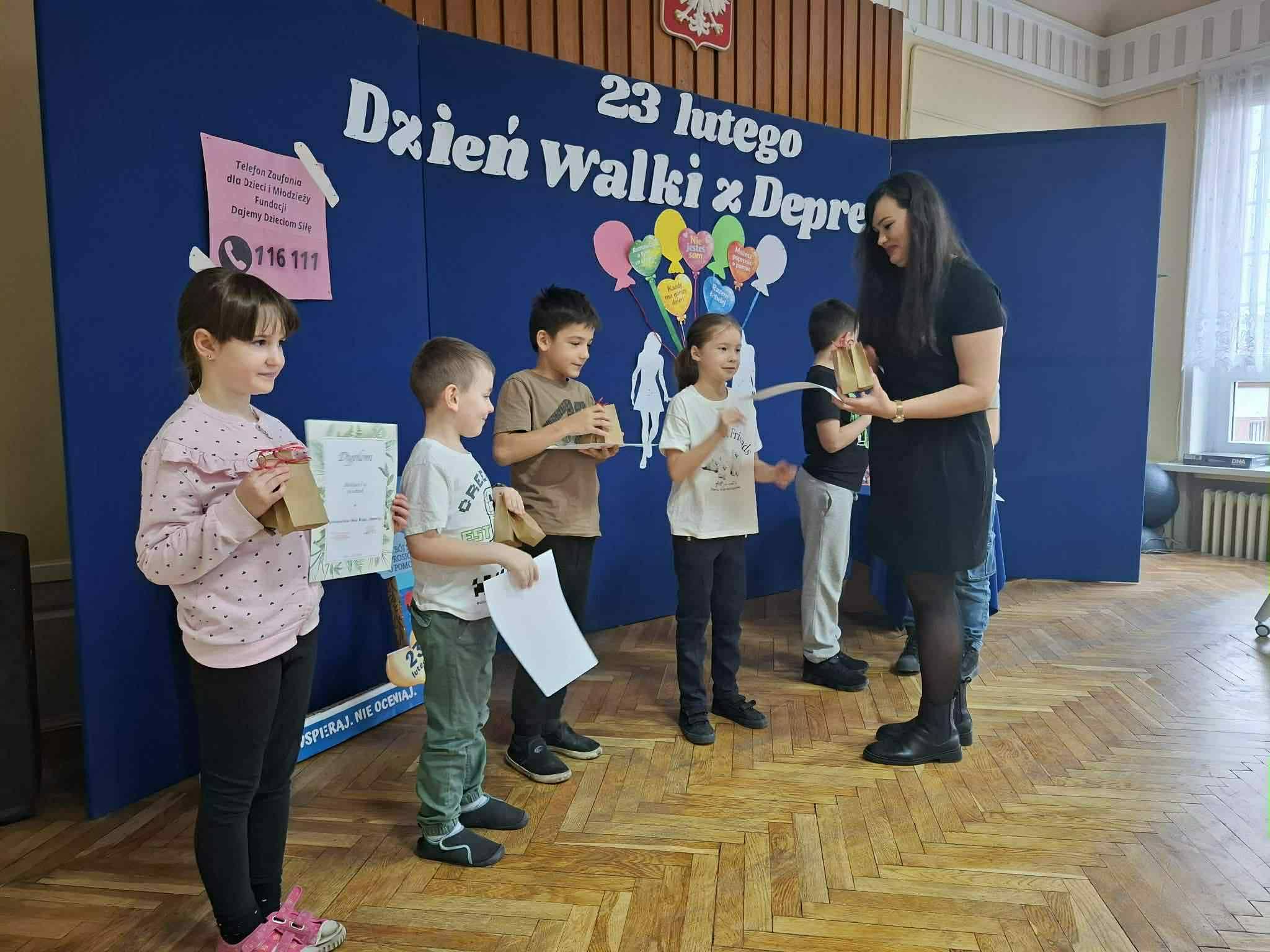

23 lutego w naszej szkole odbyły się działania profilaktyczne, edukacyjne i wspierające w ramach Ogólnopolskiego Dnia Walki z Depresją. To ważna inicjatywa przypominająca, że zdrowie psychiczne jest tak samo istotne jak zdrowie fizyczne. Uczniowie klas I–III, IV–VI

24 lutego 2026 r.

Sukces uczennicy klasy 2b Gabrysia Zawadzka, uczennica klasy 2b , zakwalifikowała się do Wielkiego Finału Ogólnopolskiego Konkursu Recytatorskiego „Cudolandia”, którego inicjatorem jest Jacek Cudny. Finał odbył się w grudniu i zgromadził uczestników z

24 lutego 2026 r.

Wyróżnienie w konkursie wojewódzkim!!! Przyjemnie nam poinformować, że uczennica klasy IIa Liliana Boniecka otrzymała wyróżnienie w konkursie plastycznym pod nazwą "Muminki w mojej wyobraźni" zorganizowanym przez Pedagogiczną Bibliotekę Wojewódzką im.

24 lutego 2026 r.

Dnia 27 stycznia 2026 r. uczniowie klas IVb, Va, VIa oraz VIIIa wybrali się na pełną wrażeń wycieczkę do Warszawy. Na początek odwiedziliśmy Sejm, gdzie dowiedzieliśmy się, jak powstają ustawy. Następnie spacerowaliśmy po Starówce, podziwiając zabytki, kolorowe kamienice i

24 lutego 2026 r.

Gramy z WOŚP! Nasza Szkoła wspiera 34. Finał Wielkiej Orkiestry Świątecznej Pomocy! Dziś odbyła się licytacja, na której nauczyciele i uczniowie mogli wesprzeć WOŚP Dziękujemy Panu Miłoszowi Makowskiemu - Przewodniczącemu Rady Rodziców za zaangażowanie i poprowadzenie

24 lutego 2026 r.