Szkoła Podstawowa nr 5

im. Jana Pawła II

w Lipnie

15 grudnia klasy VIIb i VIIIb uczestniczyły w wycieczce do Warszawy w celu poznania historii miasta oraz jego zabytków. Program wycieczki obejmował zwiedzanie Muzeum Powstania Warszawskiego gdzie uczniowie poszerzyli swoją wiedzę historyczną o wojennych losach naszej stolicy.

7 stycznia 2026 r.

Uczniowie naszej szkoły brali udział w rozgrywkach szachowych dla szkół podstawowych. W etapie miejskim dwa zespoły z naszej szkoły, grupa starsza klasy VII-VIII oraz grupa młodsza klasy I-VI uzyskały awans do rozgrywek powiatowych. Rozgrywki na szczeblu powiatu odbyły się 25

7 grudnia 2025 r.

Wycieczka do salonu fryzjerskiego. Pierwszoklasiści poznawali zawód

1 grudnia 2025 r.

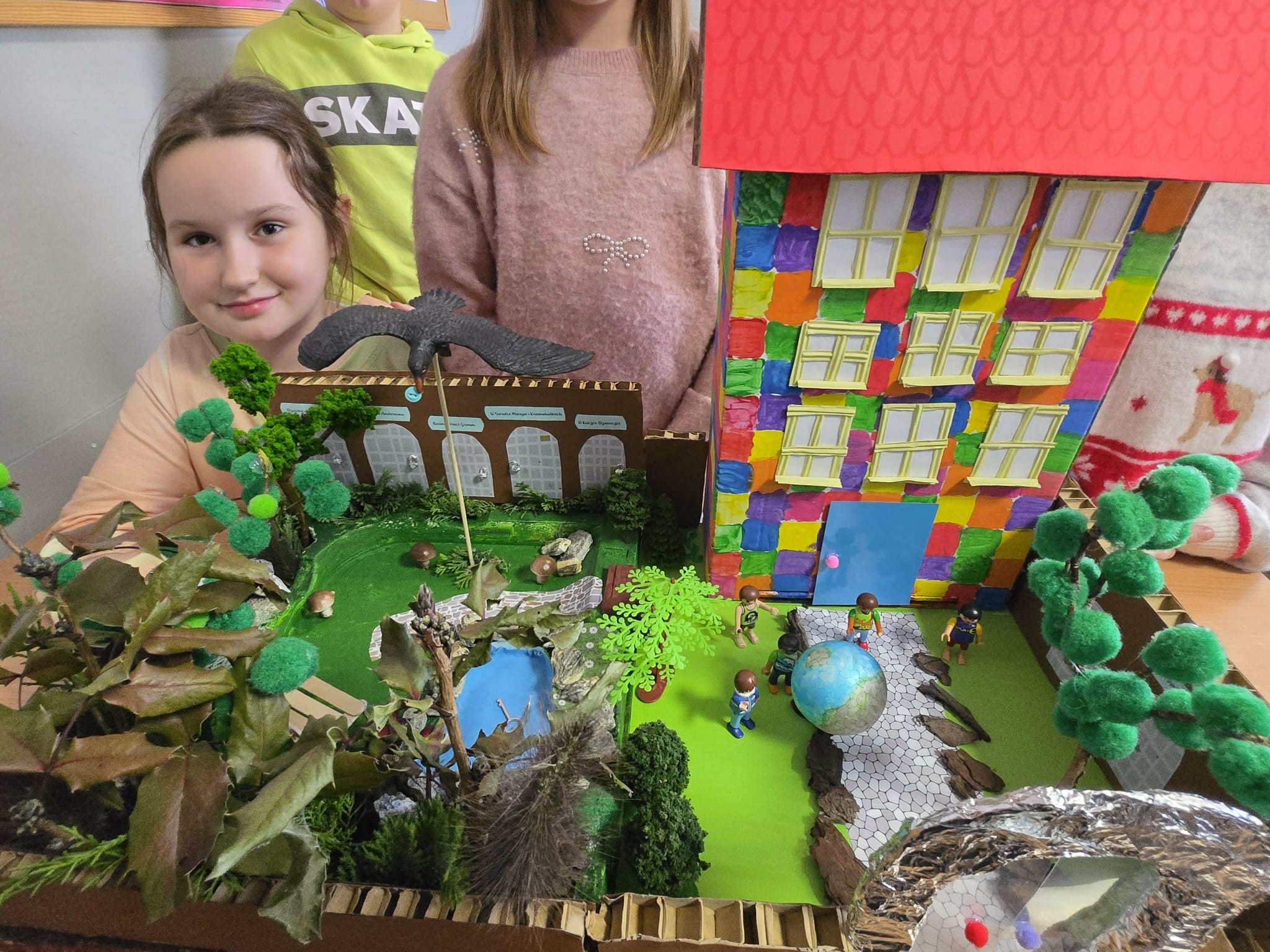

Uczniowie klas 4a i 4b na zakończenie projektu przygotowali wyjątkowe prace inspirowane lekturą pt.: „Akademia Pana Kleksa” Jana Brzechwy. W ramach działań projektowych powstały pomysłowe makiety przedstawiające najciekawsze miejsca i wydarzenia z książki. Czwartoklasiści,

1 grudnia 2025 r.

25 listopada to Dzień Pluszowego Misia! Święto obchodzone na całym świecie od 2002 roku w rocznicę powstania pierwszej pluszowej zabawki. Miś – towarzysz dzieciństwa, powiernik marzeń i trosk. Dziś celebrujemy jego niezwykłą historię! Wykonaliśmy wspólne zdjęcie, starsi

1 grudnia 2025 r.

24 listopada uczniowie klas ósmych w ciekawy sposób pogłębiali swoją wiedzę historyczną. Tego dnia gościem na lekcjach historii był pan Janusz Czapiewski, wieloletni nauczyciel historii w SP5 oraz LO w Lipnie, a także członek Federacji Rodzin Katyńskich. Powodem zaproszenia

1 grudnia 2025 r.